If unavailible, the prequalified AWS D1.1 welding procedure shall be qualified in accordance with AWS D1.1 Section 6.

Our certification program is ISO/IEC 17025:2005E accredited as well as being in conformance with AWS, ASME, API and AMS welding standards. PNL provides the most comprehensive welding qualification services in the Southwestern United States. So, a prequalified WPS does not need a supporting Procedure Qualification test Record (PQR).Governing codes that designate prequalified weld joints are AWS D1.1, AWS D1.3, AWS D1.6In simple words, we proud to say about our service:It has been prepared by the Code Experts. SMAW, GMAW, MCAW, GTAW, FCAW and SAW welding process are the major arc welding processes:-Shielded Metal Arc Welding (SMAW) or Stick welding electrode is being used for SMAW welding process-Flux Cored Arc Welding (FCAW) gas-shielded flux cored wire (FCAW-G) or self-shielded flux cored wire (FCAW-S) is being used for FCAW welding process-Submerged Arc Welding (SAW) solid wire is being used for SAW welding process-Gas Metal Arc Welding (GMAW) or MIG welding solid wire is being used for MIG welding process-Gas Tungsten Arc Welding (GTAW) or TIG welding rod or solid wire is being used for TIG welding process-Metal Cored Arc Welding (MCAW) metal cored wire is being used for MCAW welding processMode of process application for all the major arc welding process:Welding wherein the entire welding operation is performed and controlled by hand.Welding with equipment that supplies continuous wire feed with or without means for mechanical travel. B) Prequalified AWS D1.1 welding procedures may not be supplemented with PQRs or revised in any SMAW, GMAW, GTAW, FCAW and SAW welding process are the major arc welding processes:AASHTO/AWS D1.5/D1.5M Bridge Welding Code (AASHTO/AWS, 2015) and the AWS. A) The manufacturer or contractor may not deviate from the welding conditions specified on the prequalified AWS D1.1 welding procedure.

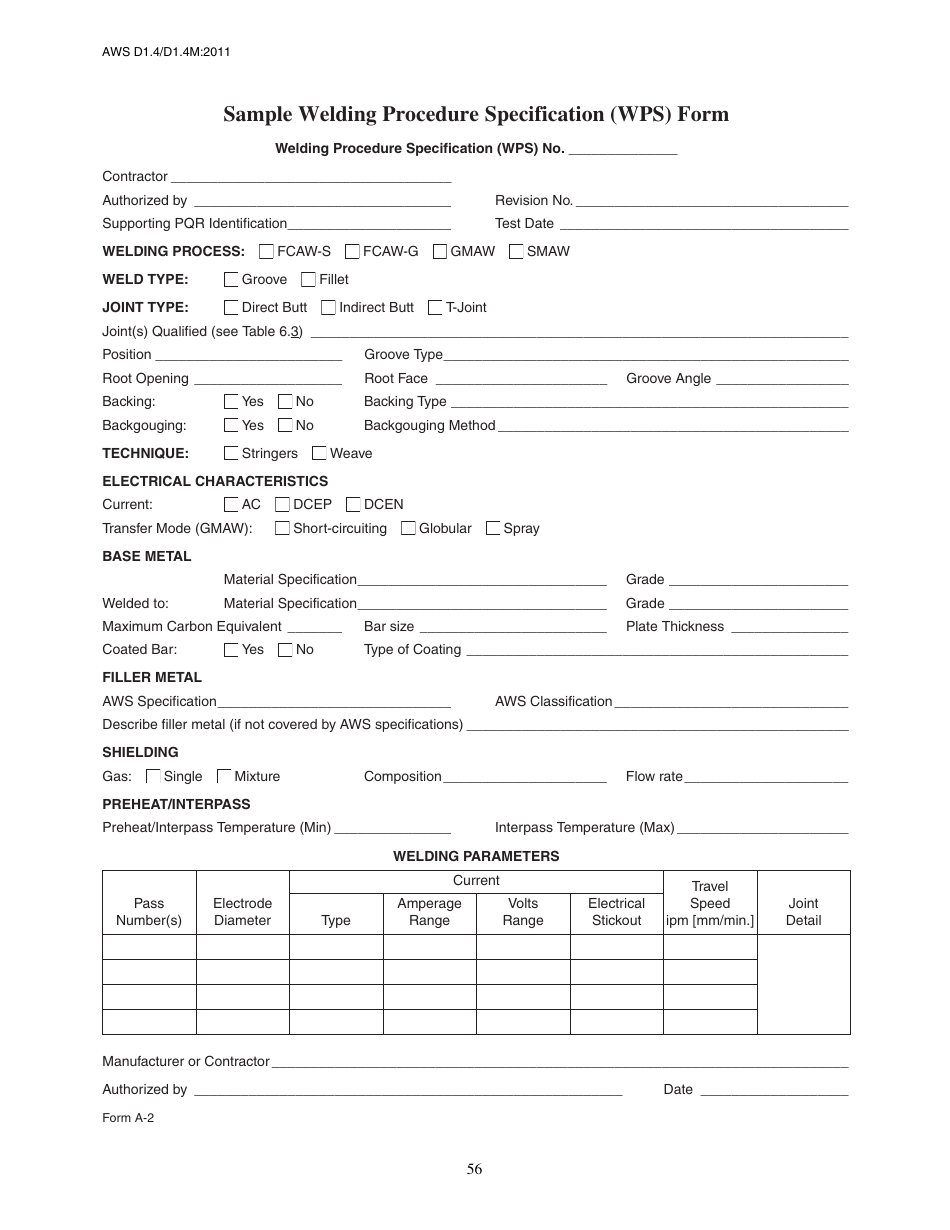

Identify all essential variables and non-essential variables required to be covered by the WPS. Determine desired welding process based on the job, company equipment, etc. In order to build a WPS following the traditional route, the following steps are required to be performed IAW AWS D1.1

Once the non-destructive examination is completed, you’re ready to cut test specimens out and bend/pull them in accordance the requirements in Table 4.2, 4.3, or 4.4 depending on your test type.Prequalified Welding Procedure Specifications – The AWS D1.1 committee established prequalified WPSs to alleviate the need to test the most common processes on the most common base material year after year, decade after decade. This volumetric exam is often overlooked by companies, and an easy find for auditors. In addition to a visual examination, volumetric examination is required, either UT or RT. Perform qualification tests – once the WPS qualification coupon is welded out, a visual examination of the cap and root (if open root) must be performed. Perform WPS qualification test, recording all variables for entry onto the PQR. Purchase, or machine WPS qualification coupons.

A high level summary of the limitations are: If a company writes a WPS in accordance with Clause 3, not procedure qualification is required, which exempts them from the testing, PQR, and other qualification requirements. The use of Prequalified WPSs is ideal for companies who generally work on industry standard, typical jobs, such as structural steel building, enclosures, supports, etc. In order for a company to take advantage of this effort, they simply need to follow the limitations laid out in Clause 3, including essential variable, base material, joint detail, and welding process limitations. As a result of this effort, AWS added Clause 3 Prequalification of WPSs, to the welding code.

Examples include amperage change limits, PWHT addition or deletion, etc. The variables outlined in Table 3.8 for the given process must be met, and fall within the limited range. Again these are common sense, and typical what one would see in a qualified WPS. Preheat and Interpass temperatures must meet the requirements in Table 3.2. The list is expansive and covers most materials one would expect to see in a common AWS D1.1 job. The base materials and filler materials must be listed in Table 3.1 of the Code.

SWPSs cover a wide range of welding processes, materials, and joint configurations, and can be purchased from AWS for around $200/ea. AWS and its members collected hundreds of PQRs from the industry, sat down and reviewed them as the “Welding Research Council”, and developed a set of industry wide WPSs based on these PQRs. Other design and fabrication limits that in the opinion of the author are pretty common sense.Standard Welding Procedure Specifications (SWPSs) – The third and final option for developing a WPS for use in a structural steel application is SWPSs. AWS isn’t going to let you weld a new configuration, without requiring you to qualify the weld procedure.

0 kommentar(er)

0 kommentar(er)